Thermal Printer Maintenance – How to clean a thermal printer head

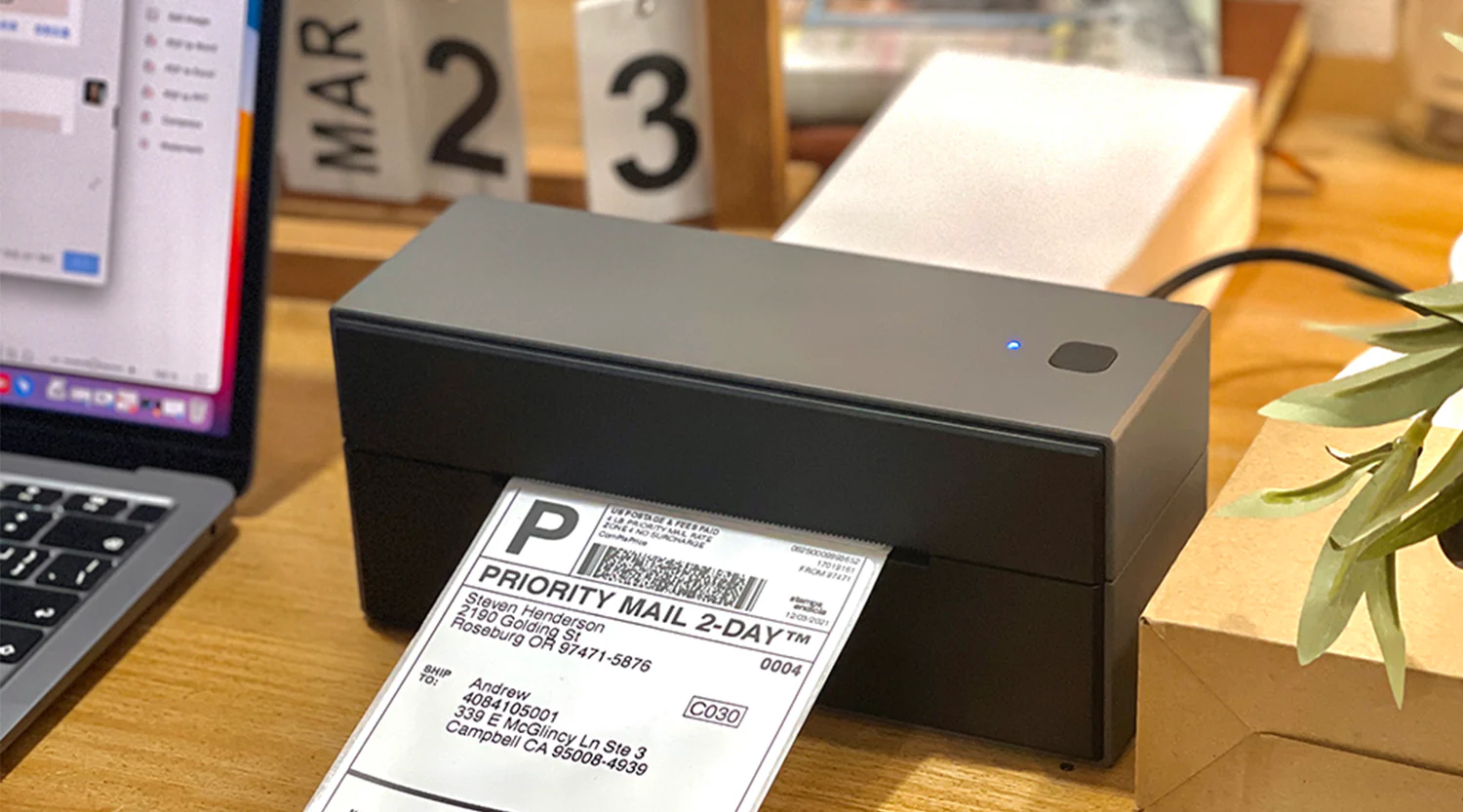

A thermal printer is a device that makes printed characters by melting a thermal wax ribbon onto a label or sheet of paper. Barcodes are printed on labels and tags using thermal printers. In most cases, replacing the ribbon in a thermal printer also necessitates cleaning the print head. The thermal print head is the most expensive consumable for a thermal printer. Thus, keeping it clean will save you money in the long run.

If your printer is experiencing any of the following issues, it may be time to clean the printer head:

- However, the thermal paper is fine, even though the printer’s output is blurry.

- This printer does not make it obvious that it should print pages in landscape orientation.

- The paper-feeding and printing processes are becoming increasingly loud.

The quality of the thermal transfer ribbons and paper material used while printing, as well as environmental conditions like humidity and dust, can all affect the printing quality of your printer. Use only high-quality supplies and keep the printer clean for optimal output.

The efficiency of the print head is the most important factor in ensuring crisp, high-quality output. The printout quality will suffer if the printer is unclean, clogged, worn, or abraded. Your printer’s print head and lifespan generally benefit from regular cleaning and maintenance. And because print heads are so costly, any effort you make to keep them in good working order and extend their lifespan will pay for itself You can even maximize the print quality of your printer. Some preventative measures include:

Labels, medium, and ribbons must be right:

Make sure you have the proper labels and adhesives for your printer. If you do this, you can still print high-quality labels using less power. Using low-quality media can lead to label quality concerns, such as dust or particle buildup, which can lead to poor scanning or labels that don’t satisfy customer criteria.

Maintaining a clean printer head and body is essential.

Because thermal printer heads are so delicate, keeping them clean is essential for prolonging their useful life. Safe methods for cleaning the printer head should be detailed in the printer’s instruction manual. Remember that cleaning the head with harsh chemicals or an abrasive cloth could cause permanent harm. It’s also a good idea to give the inside of the printer a soft wipe-down to remove any dust that may have settled in. You can get better print quality and longer printer life by keeping the printer and print head clean.

Always use cleaning and maintenance products as directed:

This step is essential to ensure that your thermal printer is functioning properly. If you use a thermal printer, remember to clean the platen roller and printhead every time you swap out the ribbon. After every two or three rolls of labels have been used in a direct thermal printer, those parts should be cleaned.

To avoid wasting ink, printing at the slowest speeds possible faster speeds will generally shorten the printer’s life. Don’t crank up the brightness and atmospheric pressure. Also, be mindful of the platen roller as you swap labels.

Make sure the settings fit your needs:

Most thermal printers have options for customizing print quality and speed. The printer will suffer more wear and tear if faster and better printing is also attempted. You can lessen the stress on your thermal printer and potentially increase its lifespan if you discover that the settings’ performance exceeds your present demands.

Dust residing:

Having dust on the Media Sensor can lead to serious maintenance concerns. The Media Sensor keeps the distance between the paper and the printhead consistent. Most users buy a can of “canned air” and blow quickly into the Media Sensor to get rid of any dust that may have accumulated from using roll paper. You should think about doing this every time you replace the ribbon or a paper roll. In exchange for a minimal investment of time, you will receive significantly more reliable service.

Label quality:

Since the labels are in regular touch with the print head, their quality is crucial to the longevity of the print head. Low-quality labels might leave a deposit of dust and glue on the print head, reducing print quality.

How to clean the thermal printer head?

Rubbing alcohol or isopropyl:

A wipe or swab soaked in isopropyl alcohol can clean the printhead. Zebra says swabs are the most secure method. You can also use a lint-free cloth, but make sure you use rubbing alcohol with the highest purity percentage feasible.

- When the printer’s top cover is opened, a cleaning pen or cotton swab soaked in diluted alcohol or isopropyl should be used to wipe down the printhead from the center to the sides.

- Wait a while before using the printer again after that. Make sure the printhead is dry before turning it on, and give the alcohol a minute or two to evaporate.

It’s important to clean the print head with enough force to get the job done but not so much that you damage the mechanism. Repeat this process numerous times to ensure a clean print head. After the printhead has dried completely, you can resume printing.

Cleaning Cards:

Cleaning cards are another viable option for getting the task done. Cleaning cards remove debris from the printer’s rollers and the print head. However, cleaning cards should only be used occasionally, as repeated abrasion could eventually damage the print head if used too frequently.

Tips on how to clean printer heads:

- The print head mechanism must never be opened, nor any cleaning supplies be used while the printer is active.

- Before cleaning, blow gently inside the print mechanism to dislodge any loose dust particles.

- When cleaning the print head, avoid touching the hot part.

- Static electricity and other environmental factors might cause serious problems for the printer head.

- Do your best to keep the print head free from scratches and other damage.

- Take off any jewelry, including watches, that could scratch the print head or its surroundings.

- Avoid contacting it anywhere besides its edges to keep the printhead glass in good condition.

Frequently Asked Questions:

Q1: What could it be necessary to clean the print head?

A: The printed docket you receive may occasionally be incomplete or discolored. In most cases, the print head in your thermal printer is to blame and could benefit from a simple cleaning.

If this doesn’t solve the problem, you may need a new printer or print head, depending on the make and model.

Q2: When does a printer require servicing again?

A: A printer’s maintenance kit, in particular, should be refreshed every two years. The least minimum is once a year, but ideally, it would be more like twice a year. Having your devices checked out regularly is a good idea, even if you don’t believe they need it because they’re working properly.

Conclusion

The article’s conclusion states that you should always verify that the labels you are printing are suitable for your printer to get outstanding results. Using laser material with an inkjet printer could cause blurring and spreading since the material won’t absorb the ink, and the ink won’t dry correctly. So, you can’t get the desired result when using the wrong material with the wrong printing method. That’s why laser label printing with an inkjet printer is not recommended.